Highlights

- Power supply by 3AC-/DC-board network or vehicle battery

- V/f-control for compressor motor

- Soft start function for compressor motor

- Control and monitoring of the entire air supply unit

- Communication with TCMS via binary inputs/outputs

- Diagnostic interface via Ethernet

Technical description

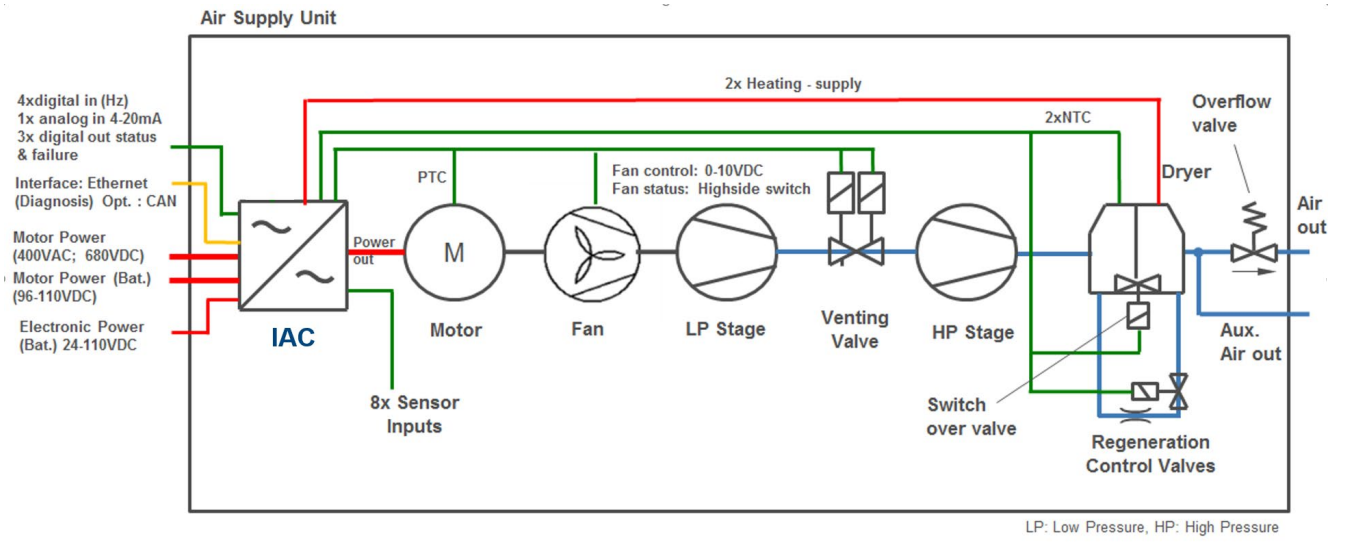

The IAC inverter is used as the central control unit of the air supply unit within a rail vehicle. The following functions are realized by the IAC:

- Control of the compressor speed

- Dryer control depending on compressor speed (changeover/regeneration logic and heating control)

- Operation of the compressor on the DC vehicle battery

- Motor temperature monitoring

- Basic inverter diagnostics (e.g. voltage and current monitoring)

- Control of an e-fan

- monitoring of the air supply unit (e.g. air pressure)

- (optional) Communication via CAN with TCMS

The IAC inverter is supplied from the 3AC/DC on-board power supply grid or the DC vehicle battery (optional).

Technical Data

| Input voltage | 3AC 400 / 480 V (IT / TN power supply acc. to EN 50533:2012, Class 1) DC 480 V ... 780 V (insulated DC grid, OV2) |

|---|---|

| Output power | 14kVA/26kVA |

| Output voltage | 3AC 0-330 V, 0-70 Hz |

| Output current | 25A/40A |

| Communication | CAN / Ethernet (Diagnostic) / 4 x DI / 3 x DO / 1x AI 0-10mA |

|---|---|

| Control voltage | DC 24-110V according to EN 50155 |

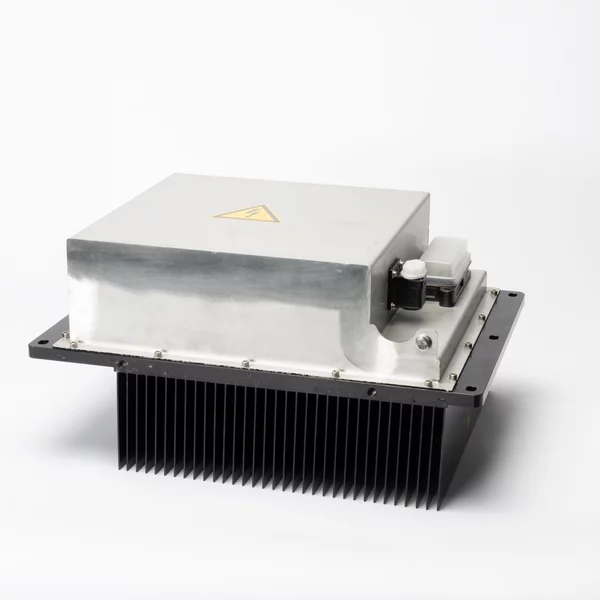

Mechanical Data

| Dimensions (L x B x H) | 540 mm x 380 mm x 260 mm |

|---|---|

| Weight | 40 kg |

| Protection class | IP 65 |

| Cooling | Natural convection |

| Ambient temperature | -40 °C … +55 °C |

| EMC | EN 50121-3-2 |

|---|---|

| Fire protection | EN 45545 |

| Design of electrical connections | Plugs |

![[Translate to English:] Rail vehicle electrification & technology](/fileadmin/_processed_/c/a/csm__ahe0223_928aee05ca.webp)

![[Translate to English:] Modernization for many additional years of operation](/fileadmin/_processed_/3/4/csm_essen_4f49d40e59.webp)

![[Translate to English:] ESU - Schalke](/fileadmin/_processed_/b/3/csm_schalke_project_2024_af42a053b0.webp)

![[Translate to English:] SmartHybrid - Vossloh DE 18](/fileadmin/_processed_/d/8/csm_vossloh_rolling_stock_de_18_370b5f1326.webp)

![[Translate to English:] Our sales team is happy to answer any questions.](/fileadmin/_processed_/7/e/csm_istock-540531658_8a109bff79.webp)